Details

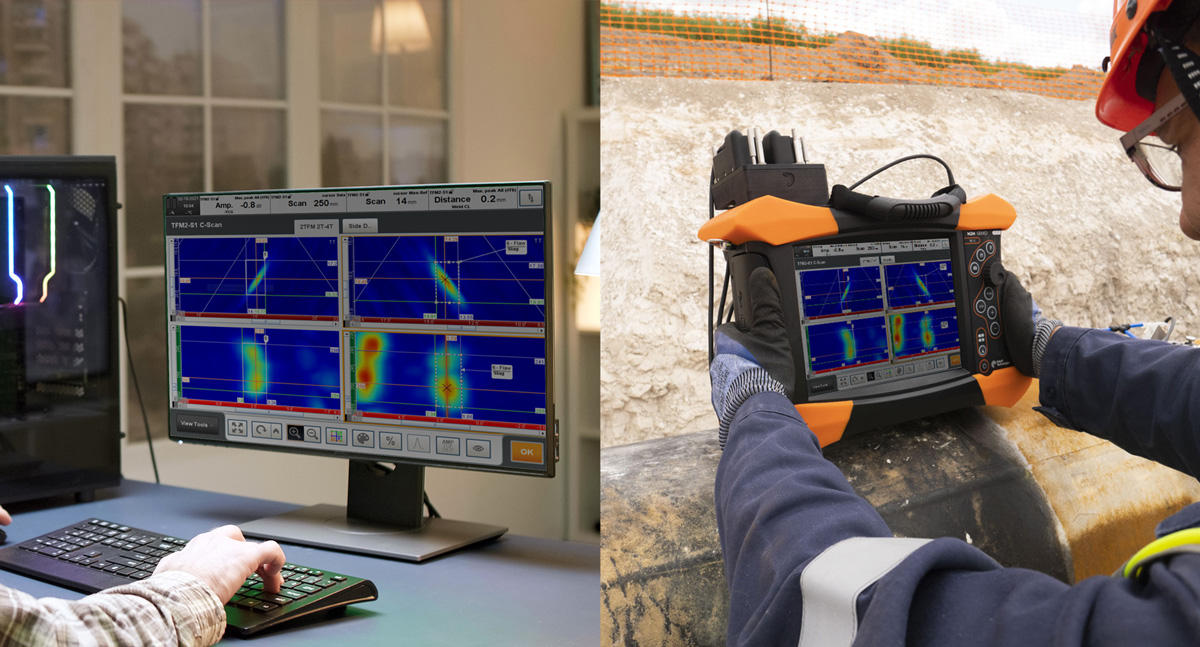

One UT software from setup to reporting

All the same intuitive software tools and features are available in the Gekko and Mantis instruments and the PC version.

- Application-oriented templates, step by step setup configuration

- Complete probe, wedge, and scanner libraries

- Custom probe creation, including DLA/DMA probes

- Focal law calculation with linear, matrix, DLA, DMA probes

- Scan plan for procedure compliance

- Analysis and reporting

- Customizable inspection report

Capture offers a quick way to improve knowledge and requires minimal training time for phased array inspectors. Always one step ahead, see the evolution of Capture software here.

Streamlined workflow

Calibration wizard

Unique 3-click calibration wizards

Smart calibration wizards fulfill the requirements of your existing procedure:

- Part and wedge velocity calibration

- Amplitude balancing and dead element check

- Best-in-class wedge delay + angle calibration - including AOD/COD wedges

- Beam balancing for PAUT sensitivity calibration (ACG)

- Innovative TCG calibration - including TFM

Historically, essential calibration steps such as wedge verification and TCG have been complicated and time-consuming. Capture does it accurately, quickly, and efficiently.

Ask an ExpertTFM for the field - our DNA

Benefiting from over 8 years of experience with TFM in the field, Capture offers:

- PCI phase-based technique

- Multi-probe, multi-group, and multi-mode TFM configurations including Pitch & Catch face-to-face probe

- Various transmission modes (FMC, sparse, PWI) compatible with both amplitude-based and PCI processing

- Acoustic sensitivity map for better mode selection and scan plan

- Compatible with linear, matrix, DLA, and DMA probes up to 128 elements

- Unique grid verification tool compliant with ASME-V / ISO 23865

- Typical 1 inch weld inspection from both sides up to 130 mm/sec (5 in/sec)

- Advanced component (3D CAD, nozzle, fillet welds…) inspection available for direct modes (LL, TT)

TFM offers improved data quality allowing more accurate sizing to reduce false calls in full compliance with the latest codes and standards.

Multi-group and multi-mode TFM configurations

Fully embedded scan plan

Offering advanced solutions

Capture provides advanced solutions through a streamlined workflow.

- 3-axis nozzle inspection, including parametric weld configuration

- Fillet welds (T, Y) with multi-skip ray tracing

- True CAD import

- Embedded scanner controls for the LYNCS

- Paintbrush 2D mapping with 3-axis rotating arm

- Unique Adaptive TFM (ATFM) solution for wavy surfaces

For these advanced inspections, Capture provides a higher Probability of Detection (POD) with improved and faster defect characterization.

Analysis made simple

Capture offers all the tools necessary for efficient and reliable data analysis.

- Complete set of views and custom layout edition

- Advanced readings banner

- Floating gates for enhanced corrosion data quality

- Accurate geometry display for better assessment

- Auto-detection and sizing for corrosion and weld

- Advanced reporting tools, customizable indication table

- Data stitching and export (PDF and Excel)

- Assisted analysis for butt weld inspection

Capture remains focused on simplifying analysis to improve sizing and accuracy, increase productivity and repeatability while respecting code inspection requirements.

Automatic corrosion sizing

View live Capture data on a remote PC

Connect your Capture

Capture offers full connectivity with lean data management for both devices and PC.

- Version manager & remote update from the cloud

- Easy file management and remote control through ethernet/wireless

- Multi-instance Capture PC

- License fleet management through the cloud

- Compatible with analysis software (CIVA Analysis, Ultis, NTPlot…)

Remote control and data management allow Capture to be connected to ease your daily inspection.